Battery Prototyping

Giner Labs has more than 15 years of experience in developing, testing, and prototyping next-generation battery technologies for our partners. We have taken next generation energy storage technologies from the idea-stage through to prototyping and intellectual property generation. Our partners include NASA, the Department of Energy (DOE), the Department of Defense (DoD), the Department of Health and Human Services (DHHS), National Institute of Health (NIH), as well as industry partners. We work with our customers to overcome technical challenges and advance technology readiness level (TRL). Our R&D facility is fully equipped to perform fundamental materials research, component optimization, scale-up, characterization and testing.

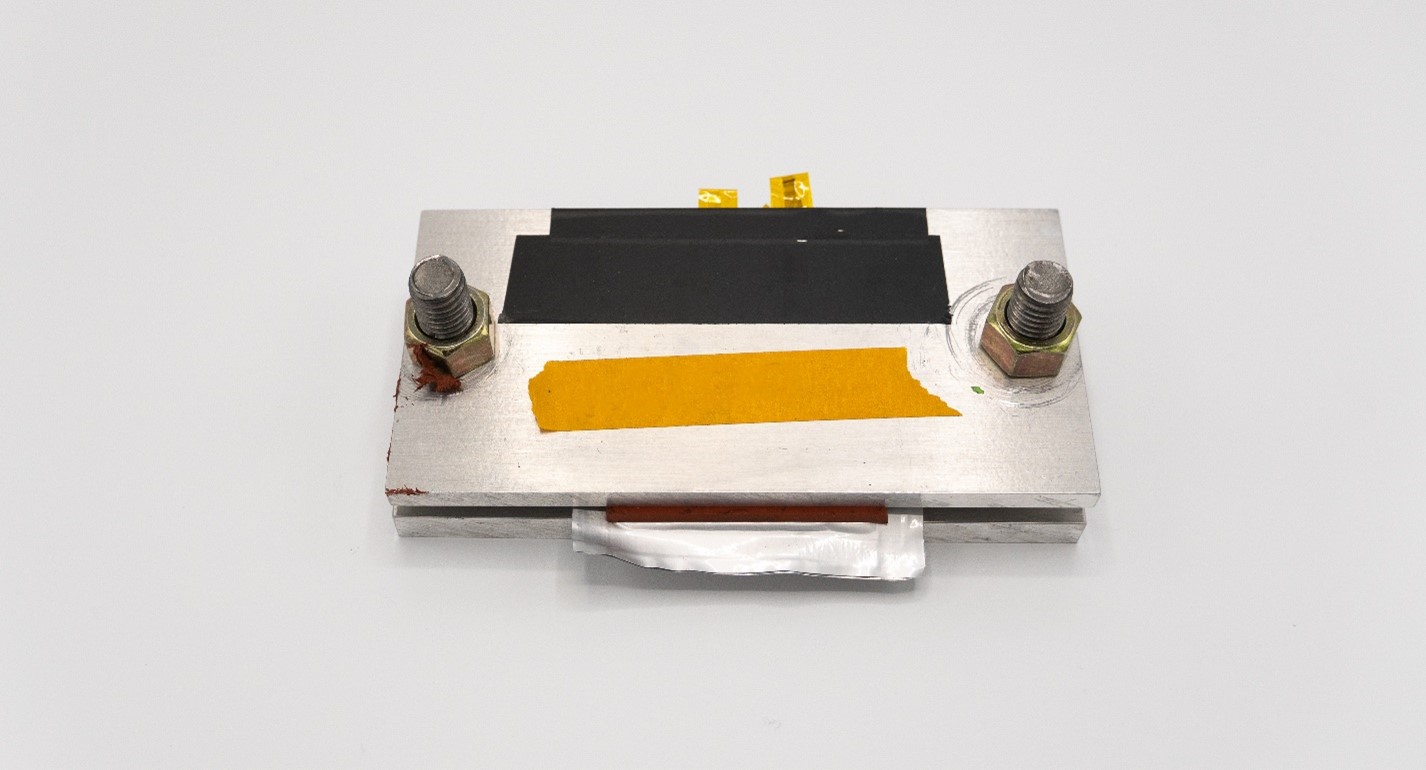

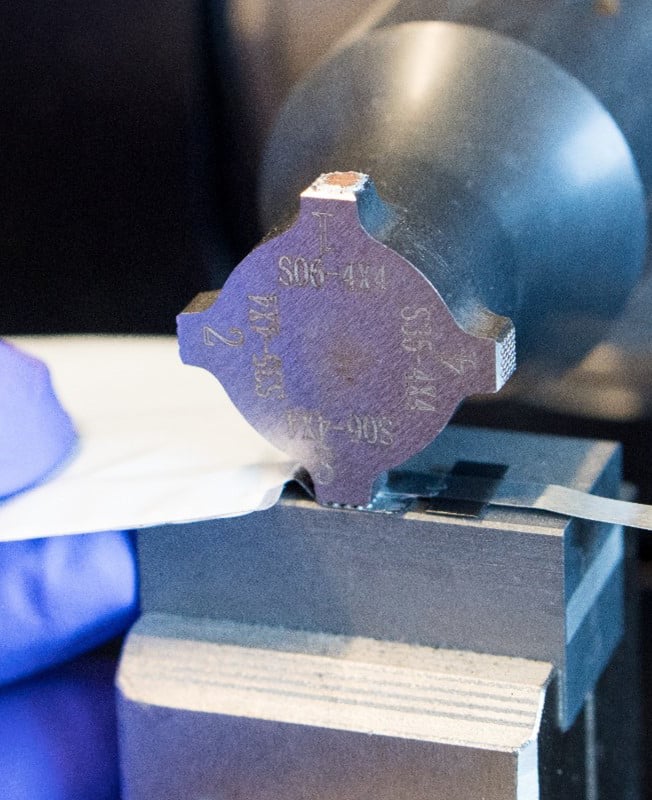

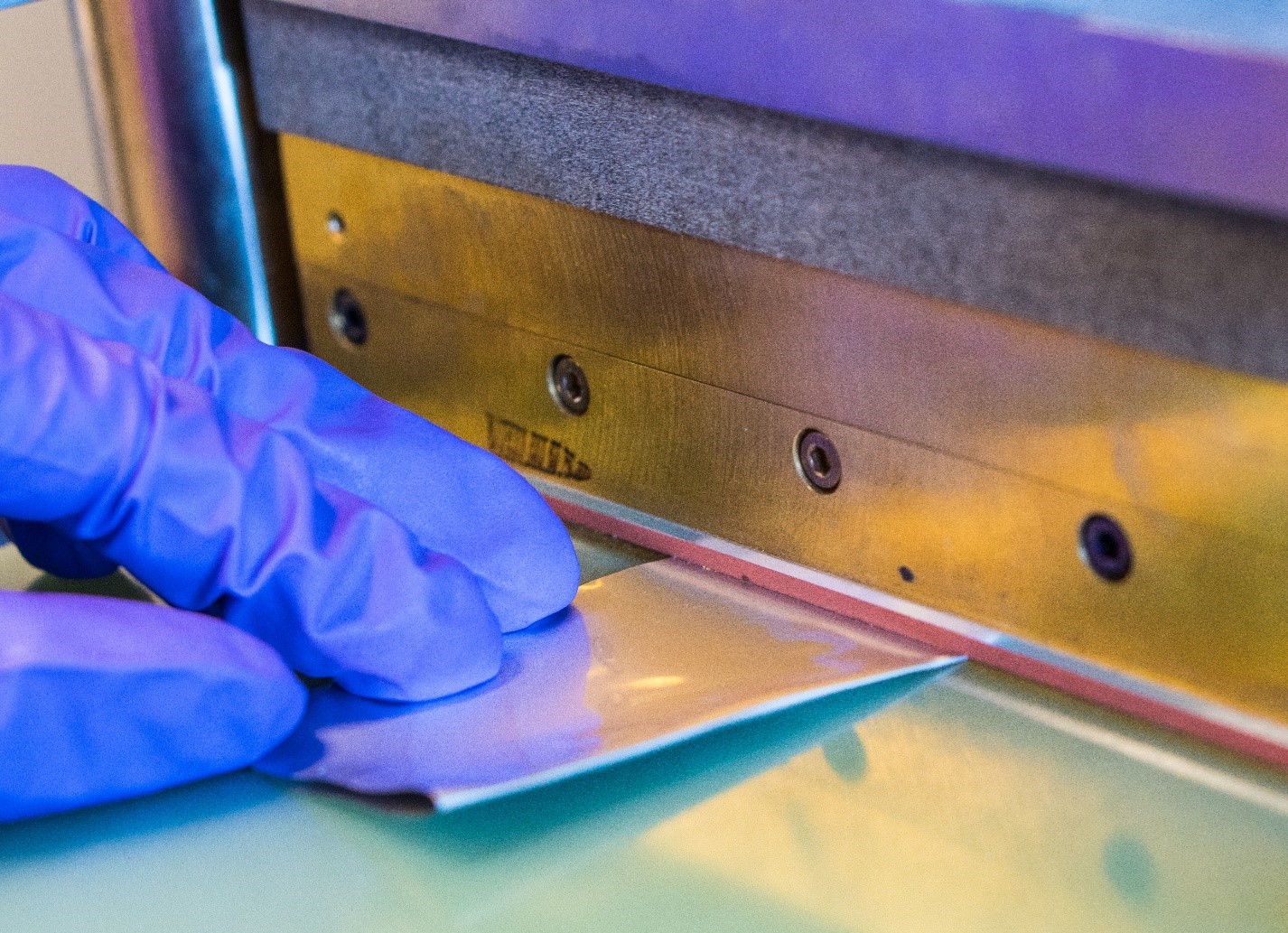

Our facility has a fully functioning battery prototyping lab. We can help you translate your materials to electrodes, conduct screening in coin cells, and fabricate and validate your technology in prototype multi-Ah pouch cells. Our capabilities include material synthesis, electrode formulation, slurry processing and troubleshooting, cathode and anode coating, component characterization, electrolyte development and cell building. Giner’s equipment includes high-temperature furnaces (tube and box), high-shear mixers, viscosity and rheology analyzers, potentiostats, optical microscopes, a scanning electron microscope, particle size analyzers, two full-length Argon gloveboxes and hundreds of cycler channels to support advancing technologies from coin cell screening to prototype pouch cells. Giner has also developed relationships with local universities who can provide timely characterization services when our needs go beyond what is in-house.

Li and Na Metal Anode Cell Assembly

Li and Na metal are attractive high energy density materials for next-generation, beyond Li-ion battery technologies. Giner Labs has over 12 years of experience incorporating Li and Na metal anodes into Li and Na-S batteries. Giner has experience sourcing, handling, incorporating, and testing Na and Li metal anodes for battery chemistries including Li-Ion, Li-S, Na-S and solid-state. We have in-house capabilities to evaluate thin laminated Li films into prototype pouch cells, up to 3 Ah. This is critical for realistic evaluation of energy density, performance and cycle life of metal anode chemistries We have also developed and patented technologies to protect these metal anodes from degradation during cycling with composite coatings and specially formulate electrolytes, providing extended cycle life and performance.

Electrochemical Cell Testing and Characterization

Electrochemical cell testing and characterization is completed in-house. Giner Labs has ~200 channels available for cycling both coin cells, cylindrical cells and pouch cells on two Maccor battery cyclers. Testing capabilities include cycle life, rate performance, electrochemical impedance spectroscopy (EIS), temperature testing down to -70°C – 100°C, pulsing, and cyclic voltammetry (CV). Electrochemical testing tracks cycle life, capacity, coulombic efficiency, rate capability and internal resistance. Through complete testing and characterization, the effect of modifications and components can be linked to performance. Post-mortem analysis and comparison of cell health at periodic intervals can be evaluated in-house through various methods including SEM, EDX, CV, and EIS, enabling benchmarking and technology impact to be quantified.