Conversion Technology Impact

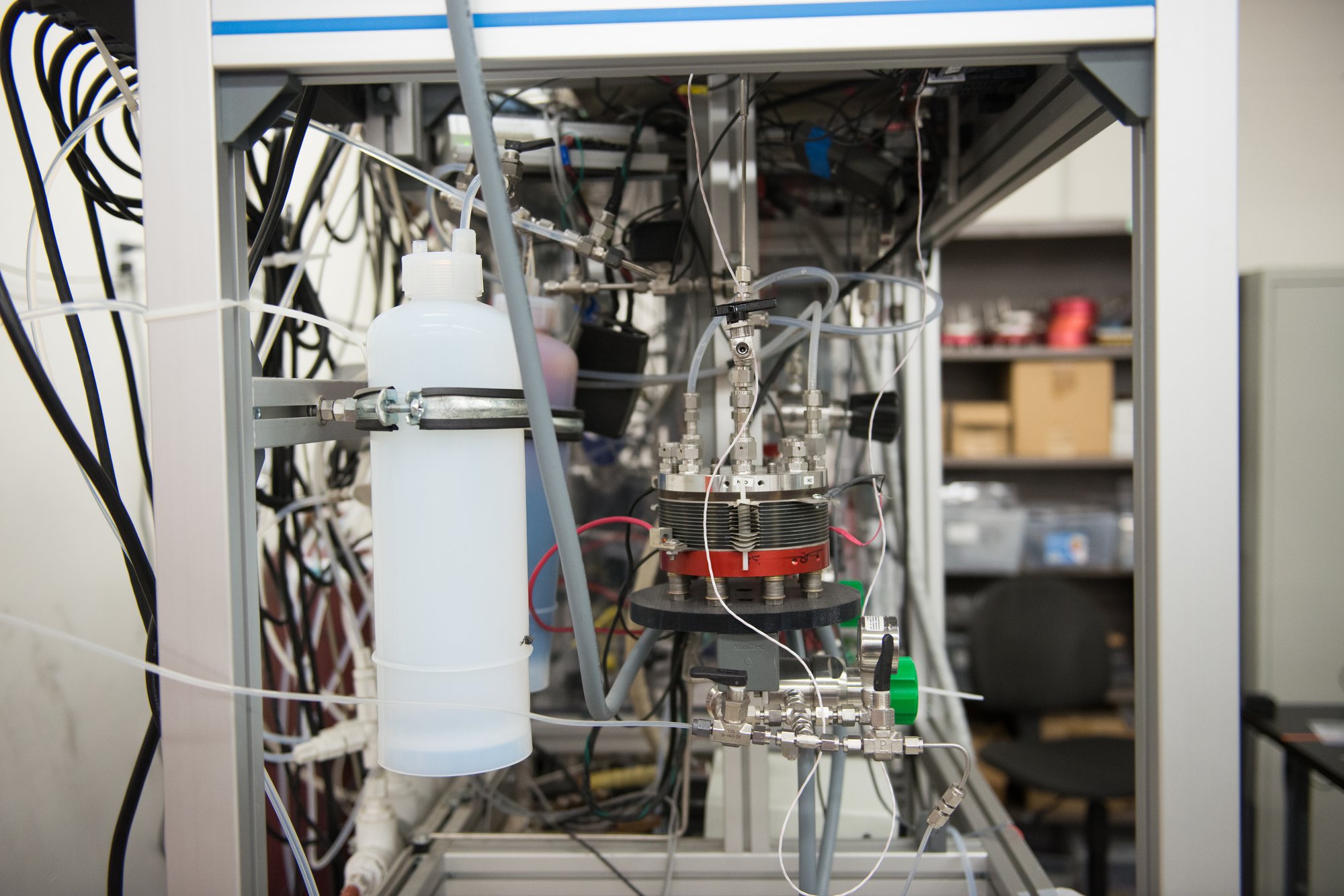

Giner has pioneered the development of a carbon dioxide (CO2) conversion electrolyzer stack, which effectively transforms CO2, water, and renewable electricity into ethylene, a highly valuable chemical.

Ethylene stands as a cornerstone in the chemical industry, with the global market reaching $176 billion in 2021 and anticipated growth to $287 billion by 2030. Its versatile applications span across packaging, automotive, construction, consumer goods, healthcare, electronics, agriculture, and more. Traditionally, ethylene is derived from petrochemical processes notorious for their carbon intensity, generating 1.5 tons of CO2 per ton of ethylene produced. Giner's green ethylene technology, however, reverses this trend by consuming 3 tons of CO2 to yield 1 ton of ethylene, resulting in a remarkable net reduction of 4.5 tons of CO2 for each ton of ethylene produced.

Selectivity and Purity

Giner is actively developing two primary technologies for CO2 to ethylene conversion. One prioritizes high selectivity, ensuring ethylene purity of 99.9%, ideal for polymerization requirements. The other aims to produce ethylene alongside carbon monoxide and hydrogen in a specific stoichiometric ratio, facilitating further conversion into alcohol.

.

Applications and Advantages

The applications of this green ethylene technology are manifold: Colocation with existing ethylene plants would allow for mitigation of CO2 emissions while taking advantage of existing infrastructure. Moreover, our technology could be used by CO2-intensive industries to convert CO2 into fuel by pairing it with ethylene upgrading technologies. Furthermore, the dynamic and rapid response time of our electrochemical approach makes CO2 to fuel conversion a valuable tool in stabilizing the grid against fluctuating renewable electricity.

.jpg?width=400&height=112&name=Greenerene%20Logo%20(properly%20sized).jpg)