Sodium Sulfur Batteries

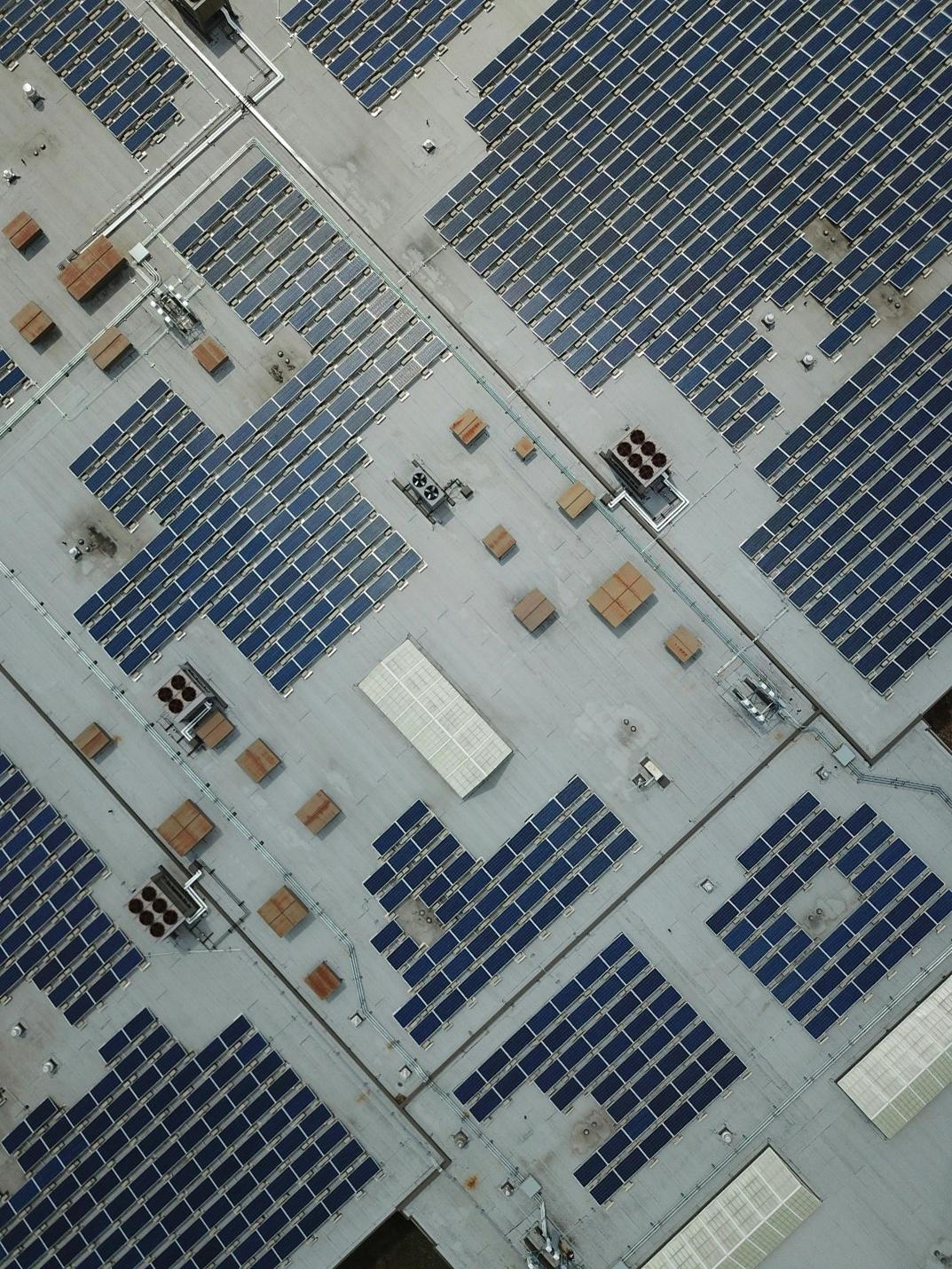

As reliance on intermittent renewable energy sources such as wind and solar increases, grid level energy storage solutions will become increasingly critical. Battery technologies based on low-cost materials with high energy density are ideal for these GW scale grid level storage facilities. Sodium sulfur (Na-S) batteries, which use sodium and sulfur as the anode and cathode active materials, offer an attractive solution. High temperature Na-S (HT Na-S) batteries are currently used for grid storage. However, they require heating to maintain operation at 300°C, resulting in low efficiency and and safety concerns relating to molten sodium.

Room temperature Na-S (RT Na-S) batteries are being developed for grid storage applications. This will provide a low-cost, high-energy density solution to accelerate the adoption of renewable energy and ensure reliable power supply to the grid. To achieve commercial readiness, several challenges must be addressed.

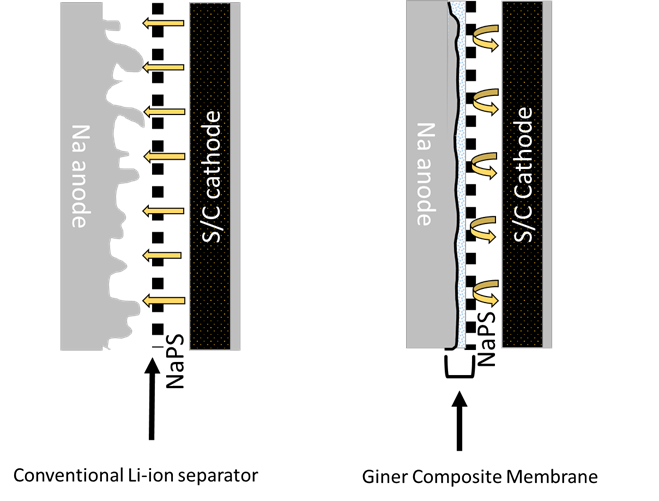

Multi-functional Separator for RT Na-S Batteries

Giner Labs has developed multi-functional separator technology which facilitates wetting with standard RT Na-S electrolytes, facilitates even current density and sodium plating, and prevents polysulfide shuttling and sodium degradation. This separator technology has reduced capacity fade in RT Na-S cells, providing a path to commercial readiness. By derisking development in RT Na-S technology by providing a separator compatible with both the chemistry and standard battery fabrication equipment, Giner Labs is advancing the availability of low-cost, high energy-density, environmentally friendly energy storage for grid applications.